| Availability: | |

|---|---|

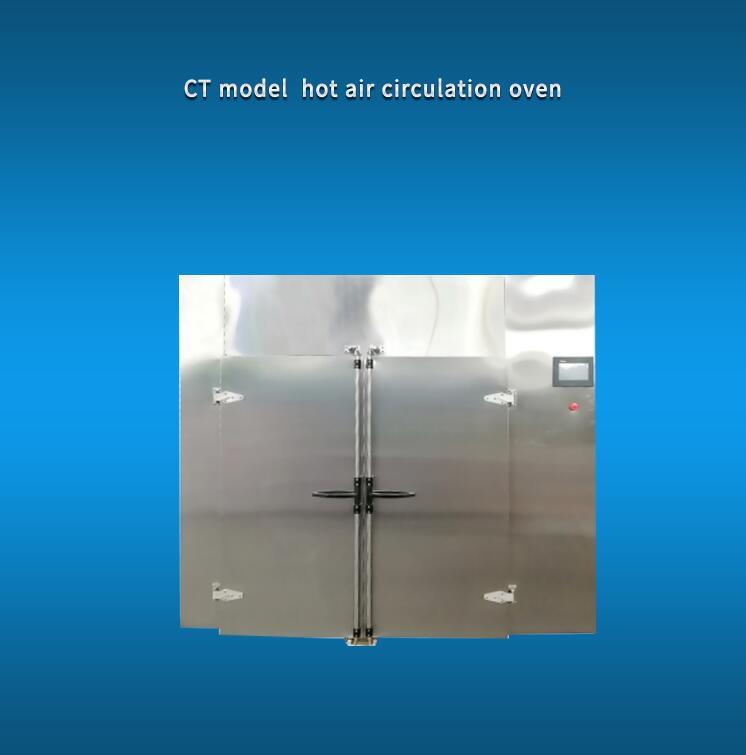

CT-C

BSIT

Shanghai, China

20 Sets/Month

T/T, Western Union, Paypal, Money Gram

1 set

wooden case packing

Single Door lab Hot Air Circulation Drying Oven Pharmaceutical Drying Machine with GMP

Application:

It is suitable for heating and solidification, drying and dehydration of raw materials in pharmaceutical industry, chemical industry, foodstuff industry, agricultural and sideline products, aquatic products, light industry, heavy industry and so on. The raw materials can be medicine of raw materials, Chinese traditional medicine, tablet of drink, immersed electuary, powder, granule, packing bottle, pigment, dyestuff, dehydration vegetable, dried fruit and melons, banger, plastic resin, electric elements, drying varnish and so on.

Working Principle:

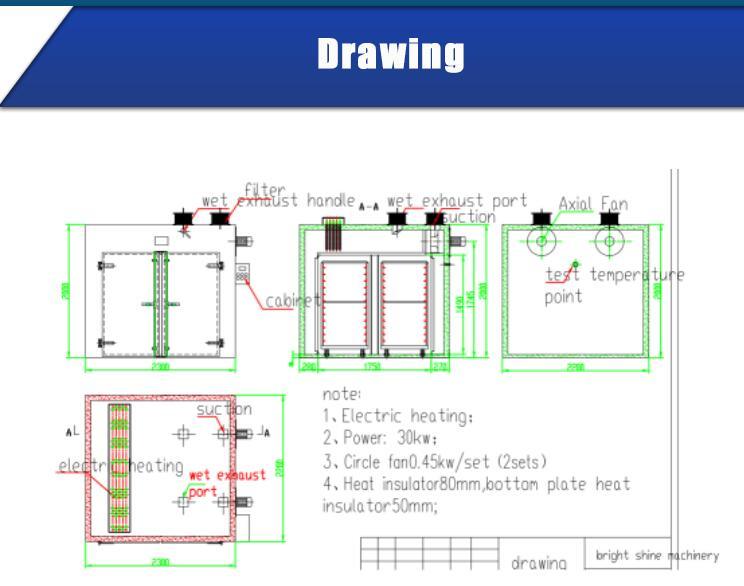

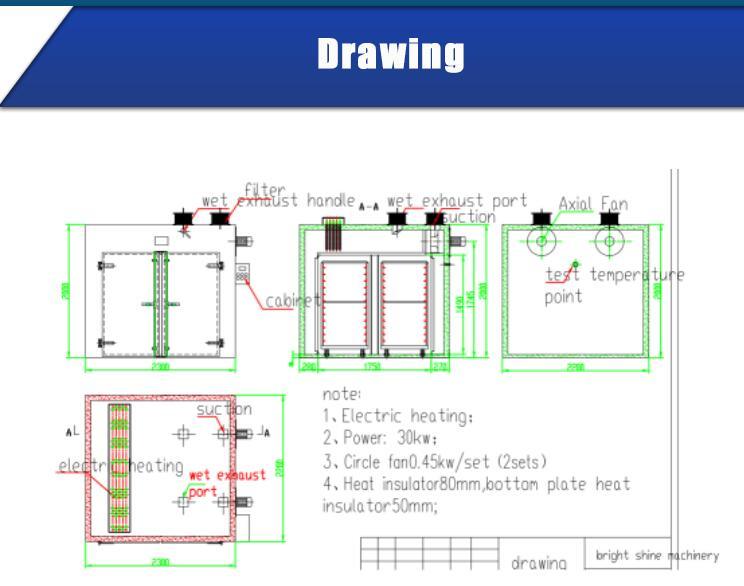

CT series Hot Air Circulating Drying Oven this adopt axle shed the air blower all, worthy of using the automatic thermostatically control system, there are control systems of a computer that for choosing. Thermal efficiency up to 70% to be about, it utilize steam or electricity heat source, flow with axle air blower heat exchanger convection change hot way heat air correctly, the laminar flow of hot air carries on heat to transmit with supplies through baking one. The fresh air is supplemented from entering the draught, abolish the damp and hot air to discharge from arranging the wet mouth, supplement fresh air with discharge damp and hot air constantly , is it keep oven proper relative humidity to come like this constantly. The greatest characteristic of this serial ovens is that some hot wind carries on circulation in the case, the whole cyclical process is closed, thus strengthened and conducted heat, has economized the energy.

Main technical parameters:

1). The hot source can be steam, electricity, far infrared, or steam + electricity.

2). Temperature of operation: 50~140.

3). 50~350 for electricity or far infrared.

4). There are automatic and computer control systems for customer selection.

5). The normal pressure of steam will be 0.02~0.8Mpa.

6). The size of drying tray: 460X640X45.

Technical Parameters:

| Parameter Type | Dry amount kg/times | Power(kw) | Consumption of steam (kg/h) | Amount of tray | Overall dimensions (mm) | Amount of trolley | Weight(kg) |

| CT-I | 100 | 1.1 | 20 | 48 | 2430X1200X2375 | 2 | 1200 |

| CT-II | 200 | 1.1 | 40 | 96 | 2430X2200X2433 | 4 | 1500 |

| CT-III | 300 | 2.2 | 60 | 144 | 3430X2200X2620 | 6 | 2000 |

| CT-IV | 400 | 2.2 | 80 | 192 | 4380X2200X2620 | 8 | 2300 |

| CT-C-O | 25 | 0.45 | 5 | 8 | 1200X1000X1750 | 0 | 800 |

| CT-C-IA | 50 | 0.45 | 10 | 24 | 1400X1200X2000 | 1 | 1000 |

| CT-C-I | 100 | 0.45 | 18 | 48 | 2300X1200X2000 | 2 | 1500 |

| CT-C-II | 200 | 0.9 | 36 | 96 | 2300X2200X2000 | 4 | 1800 |

| CT-C-IIA | 200 | 0.9 | 36 | 96 | 4460X1200X2290 | 4 | 1800 |

| CT-C-III | 300 | 1.35 | 54 | 144 | 3300X2200X2000 | 6 | 2200 |

| CT-C-IIIA | 300 | 1.5 | 54 | 144 | 2300X3220X2000 | 6 | 2200 |

| CT-C-IV | 400 | 1.8 | 72 | 192 | 4460X2200X2290 | 8 | 2800 |

Single Door lab Hot Air Circulation Drying Oven Pharmaceutical Drying Machine with GMP

Application:

It is suitable for heating and solidification, drying and dehydration of raw materials in pharmaceutical industry, chemical industry, foodstuff industry, agricultural and sideline products, aquatic products, light industry, heavy industry and so on. The raw materials can be medicine of raw materials, Chinese traditional medicine, tablet of drink, immersed electuary, powder, granule, packing bottle, pigment, dyestuff, dehydration vegetable, dried fruit and melons, banger, plastic resin, electric elements, drying varnish and so on.

Working Principle:

CT series Hot Air Circulating Drying Oven this adopt axle shed the air blower all, worthy of using the automatic thermostatically control system, there are control systems of a computer that for choosing. Thermal efficiency up to 70% to be about, it utilize steam or electricity heat source, flow with axle air blower heat exchanger convection change hot way heat air correctly, the laminar flow of hot air carries on heat to transmit with supplies through baking one. The fresh air is supplemented from entering the draught, abolish the damp and hot air to discharge from arranging the wet mouth, supplement fresh air with discharge damp and hot air constantly , is it keep oven proper relative humidity to come like this constantly. The greatest characteristic of this serial ovens is that some hot wind carries on circulation in the case, the whole cyclical process is closed, thus strengthened and conducted heat, has economized the energy.

Main technical parameters:

1). The hot source can be steam, electricity, far infrared, or steam + electricity.

2). Temperature of operation: 50~140.

3). 50~350 for electricity or far infrared.

4). There are automatic and computer control systems for customer selection.

5). The normal pressure of steam will be 0.02~0.8Mpa.

6). The size of drying tray: 460X640X45.

Technical Parameters:

| Parameter Type | Dry amount kg/times | Power(kw) | Consumption of steam (kg/h) | Amount of tray | Overall dimensions (mm) | Amount of trolley | Weight(kg) |

| CT-I | 100 | 1.1 | 20 | 48 | 2430X1200X2375 | 2 | 1200 |

| CT-II | 200 | 1.1 | 40 | 96 | 2430X2200X2433 | 4 | 1500 |

| CT-III | 300 | 2.2 | 60 | 144 | 3430X2200X2620 | 6 | 2000 |

| CT-IV | 400 | 2.2 | 80 | 192 | 4380X2200X2620 | 8 | 2300 |

| CT-C-O | 25 | 0.45 | 5 | 8 | 1200X1000X1750 | 0 | 800 |

| CT-C-IA | 50 | 0.45 | 10 | 24 | 1400X1200X2000 | 1 | 1000 |

| CT-C-I | 100 | 0.45 | 18 | 48 | 2300X1200X2000 | 2 | 1500 |

| CT-C-II | 200 | 0.9 | 36 | 96 | 2300X2200X2000 | 4 | 1800 |

| CT-C-IIA | 200 | 0.9 | 36 | 96 | 4460X1200X2290 | 4 | 1800 |

| CT-C-III | 300 | 1.35 | 54 | 144 | 3300X2200X2000 | 6 | 2200 |

| CT-C-IIIA | 300 | 1.5 | 54 | 144 | 2300X3220X2000 | 6 | 2200 |

| CT-C-IV | 400 | 1.8 | 72 | 192 | 4460X2200X2290 | 8 | 2800 |