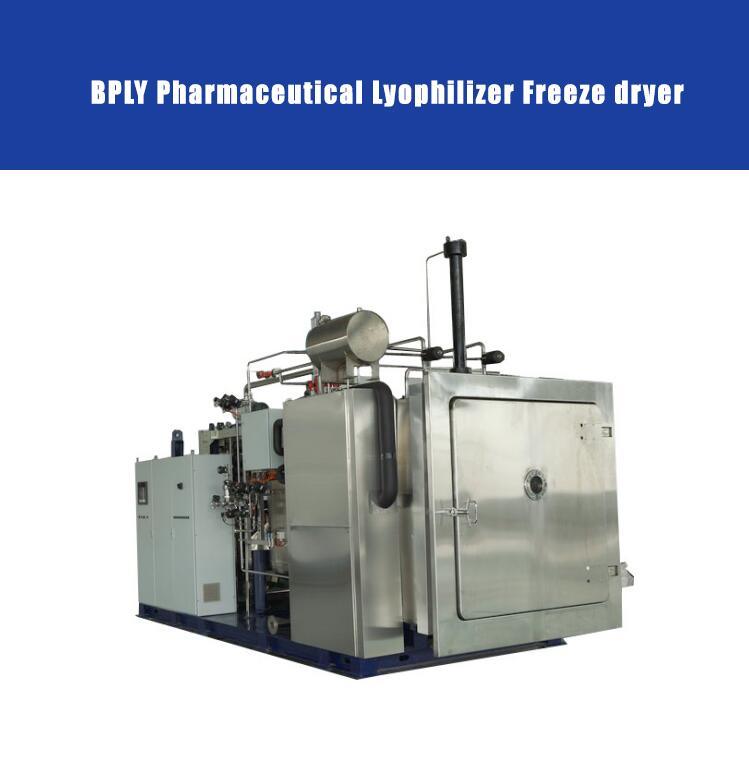

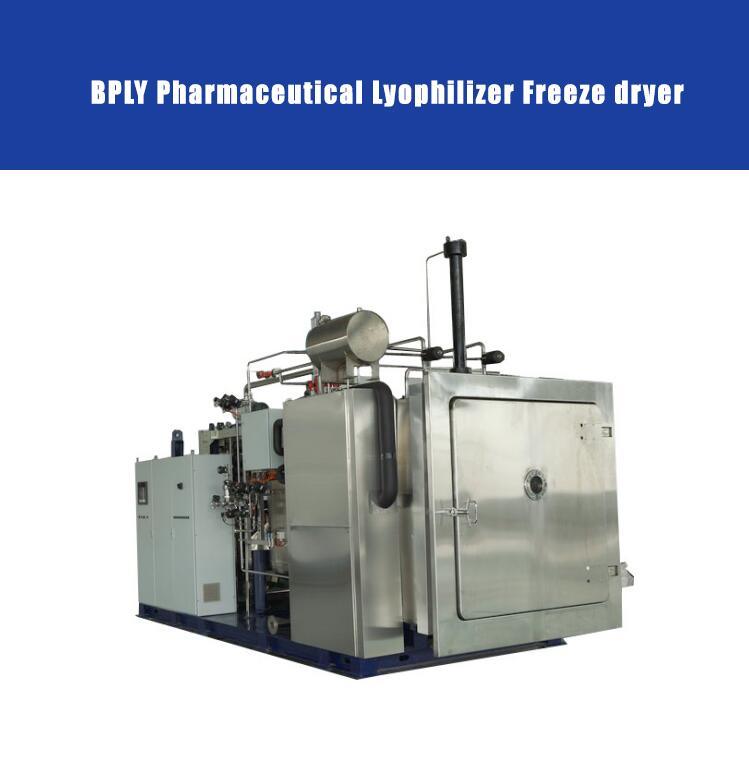

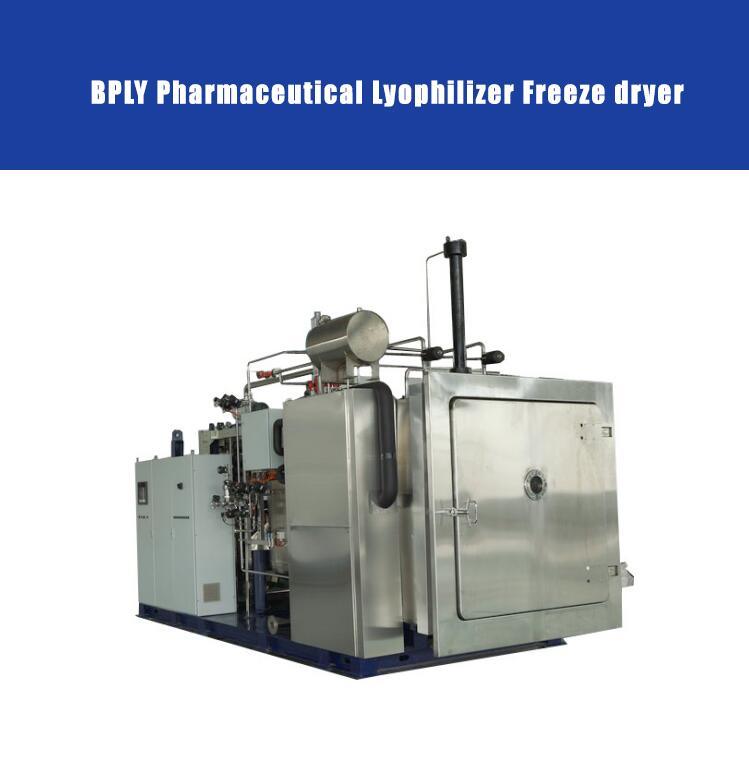

Lyophilizer Vacuum Dryer Machine Application:

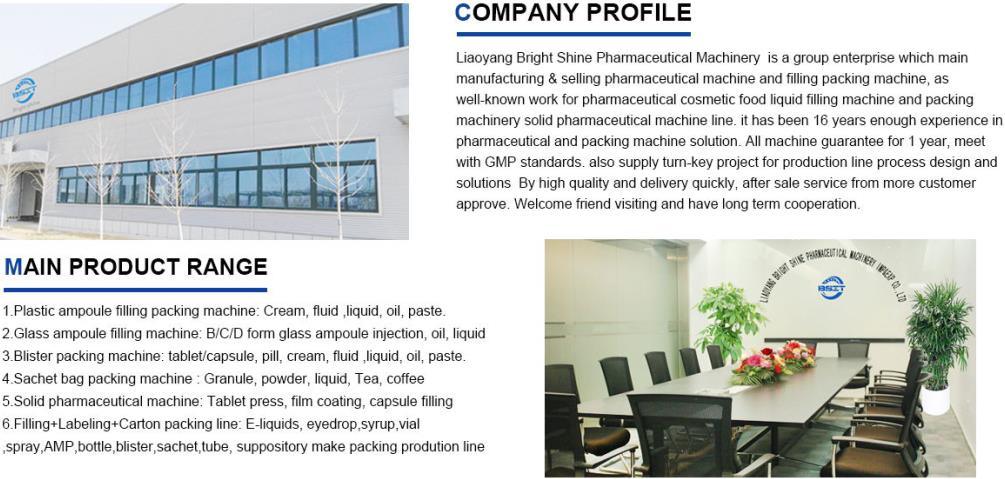

Freeze Dryer is the standard pharmaceutical Lyophilizer that allows users the flexibility to design their machines for their individual manufacturing requirements. And Freeze dryer suitabel for vial and Food Vacuum Freeze Dryer for vial and fruit and vegetable is made by our company which is designed and manufactured strictly according to GMP specifications. Every pharmaceutical plant and system is a unique and efficient combination of proven technology and individual solutions reflecting the customer needs. Based on standard components, our factory supplies plants for CGMP production configured to meet the customer's specific requirements. Highly strict disinfecting is exterminated bacterium: The freeze drier manufacture according to GMP specifications, and has the following merits: 1.All the parts contacting the products are made of AISL 316L stainless steel, the surface roughness reaches Ra≤0.5 um 2. The inner circle of the the chest has a smooth transiton without dead corner, no objects accumulated. 3. Consider for user, the structure is easy to clean 4. Option for steam sterilization or chemical sterilization. Except for the above ,we can also provide automatic running CIP( on-site cleaning) and SIP( steam sterilization) functions to ensure the high qualtiy of cleaning and the sterilization of the equipment. SIP: Use overheat pure steam (121ºC) 1. Equipped with cooling water jacket, after sterilizing, it can fast reduce the temperature of chest (if less than 20m2, the equipment is optional, if larger than 20m2 , the equipment is standard configuration). 2. Optional pneumatic door lock, it locks automatically. 3. Use import sterilization filter to ensure the absolutely sterilized air coming into equipment.

4. The chest and various kinds of container and tube are all wrapped with import insulating layer to efficiently avoid from heat transmission 5. Can carry out constant humidity control to the refrigeration humidity 6. Equipped with water circulation pump capable to eliminate residual water in sterilization layer CIP: 1. The high-pressure clean water thoroughly wash inner surface of the chest and condenser 2. Equipped with large flow rate CIP pump ,fixed with CIP tubing that automatically drains the residual water. 3. Use rotary and fixed nozzle with 360-degree spray. 4. The hydraulic system uses isolated retractable corrugated tube

CIP:

CIP: 1. The high-pressure clean water thoroughly wash inner surface of the chest and condenser

2. Equipped with large flow rate CIP pump, fixed with CIP tubing that automatically drains the residual water.

3. Use rotary and fixed nozzle with 360-degree spray.

4. The hydraulic system uses isolated retractable corrugated tube

1. Uses world famous brand e. G. Frescoed Deafness Copeland Castel Edwards and etc.

2. The system, uses double stage half sealed piston compressor to reach first class temperature reducing

Speed rate and the lowest temperature in China

3. The system, power equipped is much greater than needed to efficiently ensure the refrigeration performance

4. Digital and module design has an high protection to ensure the system to run normally and stably.

5. The powerful refrigeration system liquid spray cooling system and other protection installations keep to the best working temperature and high system reliability

6. The sensitive transuding system can provide alarm and protection in time against again abnormal running situation

7. Uses refrigerant conforming to the world environment protection requirement such ad HCFCR22 and HFCRA for choice

8. Special synthetic lubricating oil can eliminate various kinds of problem due to high temperature of normal mineral oil.

The reliable The vacuum system of the freeze drier provides a necessary pressure environment to freeze drying procedure. Cooperating with condenser it can reach the vacuum level required by the freeze-drying procedure To make the system run stably under high vacuum situation the key point is the performance of the vacuum pump and the valve seal and instrument that cooperate with the pump.

Control and optimum disposition

The control system of the freeze drier provides a reliable whole procedure control for the freeze drier. It has advanced functions of display, control, recording, printing, and alarming.

Technology parameter: | Model | LXWXH(m) | Compressor | Number of compressor ( set) | Control method | Cooling water flow rate(ton/h) | Refrigerating

Out put (kw) |

| -35 & ordm; C | -65 & ordm; C |

| LS8 | 1.3X1.1X1.8 | Copeland

Or

Frescoed | 1 | Man-machine

interface | < =5 | 7000 | 2100 |

| LS16 | 2.6X1.1X1.8 | 2 | < =10 | 14000 | 4200 |

| LS24 | 2.6X1.1X2.1 | < =15 | 21000 | 6300 |

| LS32 | 2.6X1.2X1.8 | < =20 | 28000 | 8400 |

| LS42 | 2.8X1.3X2.1 | < =25 | 35000 | 10500 |

| LS48 | 2.8X1.3X2.4 | 3 | < =30 | 42000 | 12600 |