Usages and applications: It is applicable to pack quantitative liquid ,sticky liquid ,fluid and semi-fluid liquid in pharmaceutical field, health care products, food and consmetic industries.

Characteristics: The packing machine with good stainless steel as the material, according with the CE Certification standard.

PLC control, stepless transducer control.

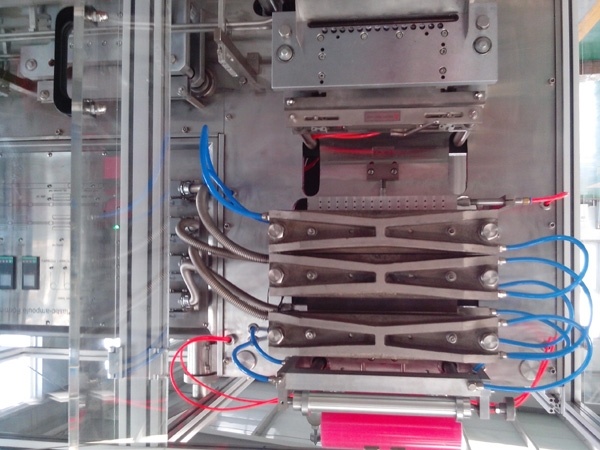

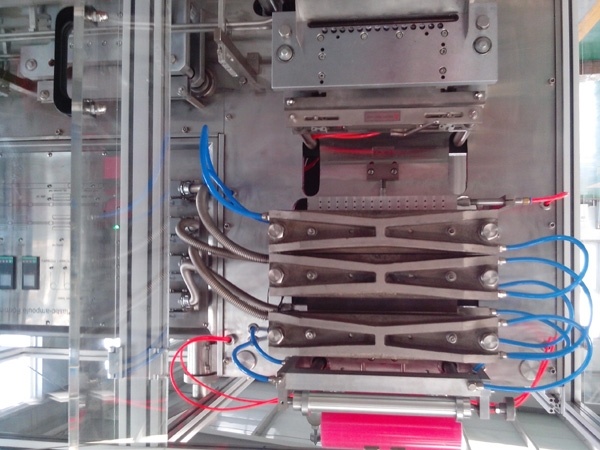

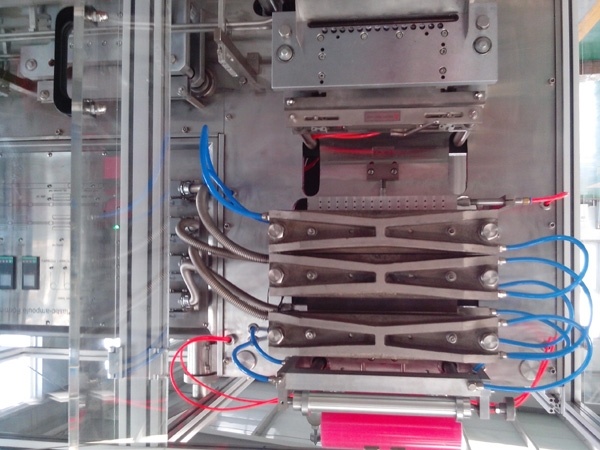

All the 22 processing units from roller spreading, forming, filling, end sealing, lot number stamping, end cutting, divide cutting, etc. Are controlled by program.

Human machine interface with easy and clear operation.

Accurate electronic peristalsis pumps filling, no drop, bubble and spill.

Main Characteristics: controlled by computer, stepless transducer, easy to operate.

wide performance range, strong adaptability, reliable quality.

small area , mo moise, save energy consumption.

beautiful outlook , new structure, reasonable layout;

changeable bottles shapes, just change the mouds to realize and easy to change moulds;

use different feeder suitable to pack different kinds of products,

low cost , easy to transport.

BDFS350 Main Technial Parameter : 1:Outside dimention :4100x1900x1860

2:Weight :3400Kg

3:Input voltage :380V 3P 50Hz

4:Power :12Kw

5:section area of power cable >6mm²

6:Max electric current15.5A

7:Air consumption :110L/min(0.6Mpa)

8:Inlet size of cooling water : Φ15mm

9:Outlet size of colling water:Φ15mm

10:Water consumption:280L/h (temperature14-18°C , pressure0.15-0.2Mpa )

11: Specification :(0.3-0.4)x345mm(max) (or according to mould size )

roll film max diameter:350mm , inner diameter of roll film :70-76mm

12:Plastic bottle per board :5-15 bottles/board(according to different filling volum)

13:Cutting frequency: 10-20time/min

14:Filling volum range : 1.5-120ml/bottle