| Availability: | |

|---|---|

DPP250

BSIT

8422303090

Shanghai, China

30 Sets/Year

T/T, Western Union, Paypal, Money Gram

1 SET

export wooden packing

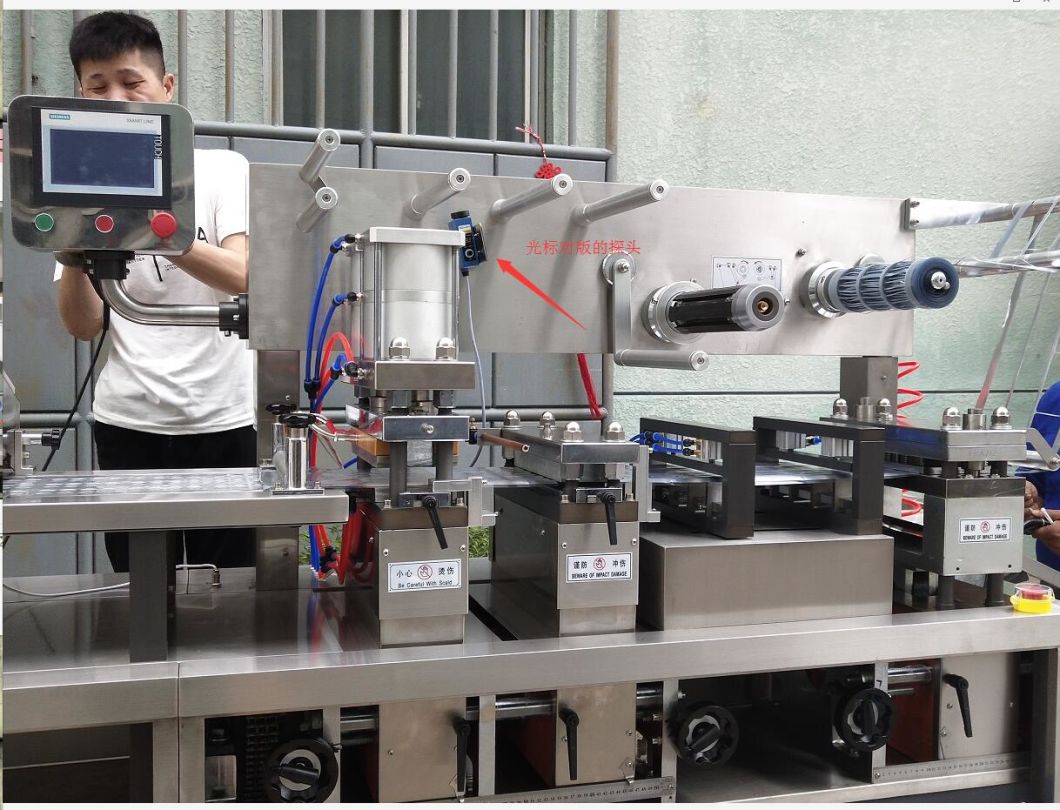

High Speed Automatic Tablet/Capsule Blister Packing Machine (Dpp250)

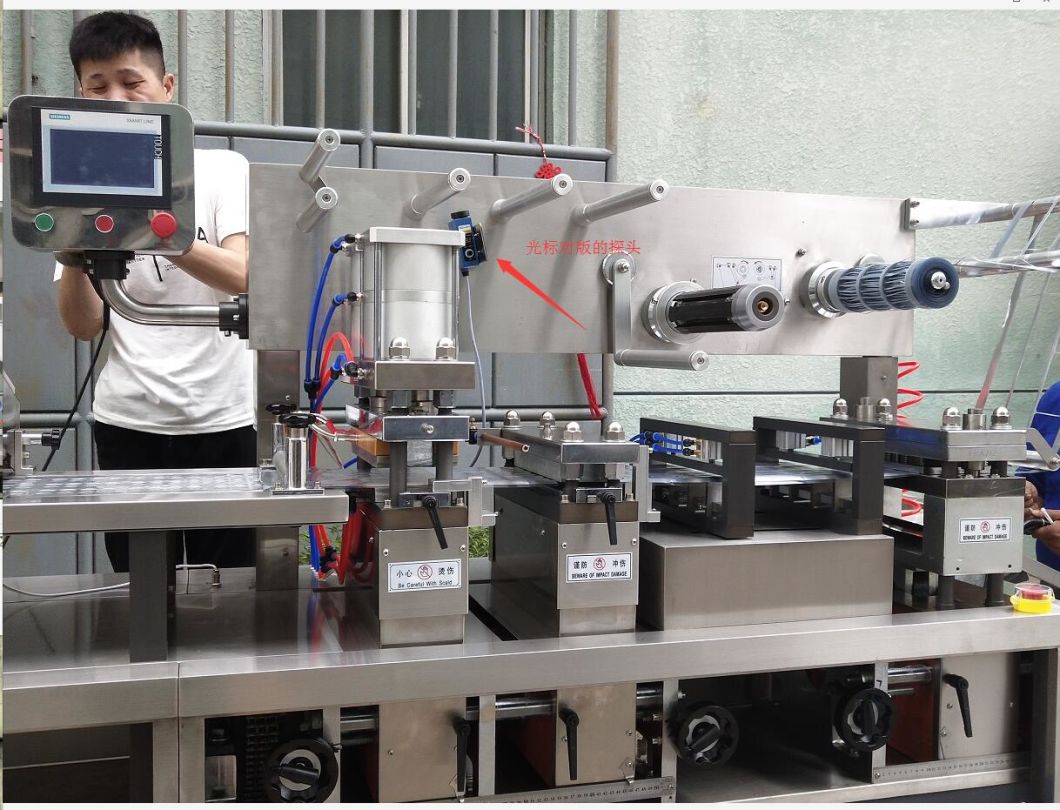

This machine is suitable for aluminum-plastic, aluminum- aluminum, paper-plastic laminated and sealed packing of capsule, tablet, sweet and deformed tablet in the pharmaceutical, food, Electronic and medical equipment industry. Besides the aluminum automatic feeding, the upper and lower texture, concavo-convex cooperating work-team, multi-stage cylinder heat sealing, automatic pressing and printing batch number and aluminum alloy double heating, the machine also has the following characteristics.

related other blister packing machine list

1. The distance among parts of forming, heat sealing and punching can be adjusted at will to fit for various medicines packing with high precision and strong usability.

2. It pulls with manipulator, adjusts travel at will, operates easily and runs reliably.

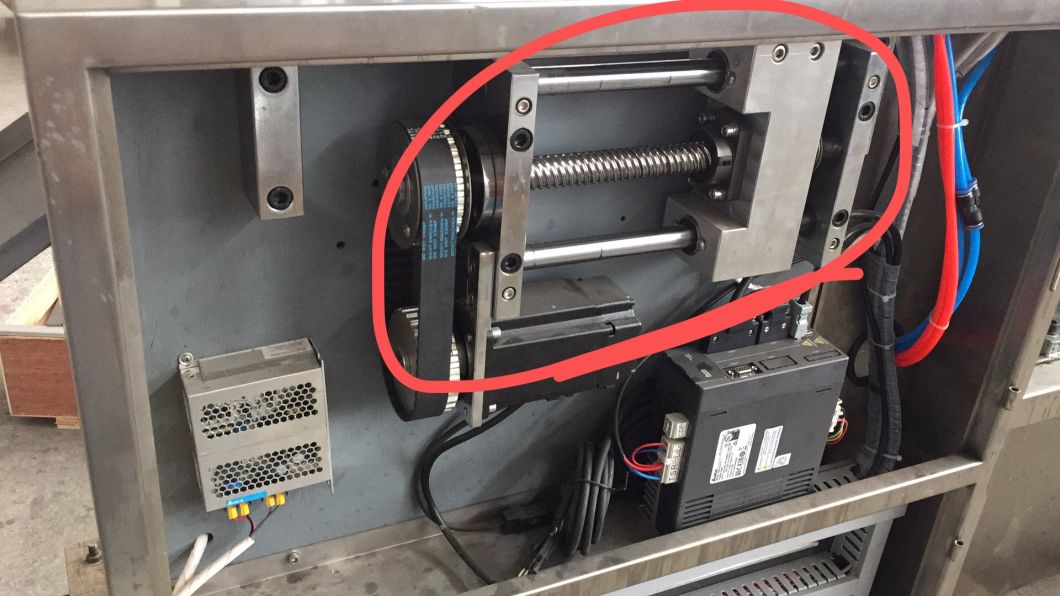

3. It adopts cycloid pinwheel to reduce speed and makes the noise low and service life long.

4. It is replaced the mould easily and accurately, adjusts speed stepless and has good performance and high efficiency.

5. The cursor alignment finishes the traction length compensating automatically.

6. Print automatically the batch Number in synchronism with ribbon.

Technical data:

| DPP140 | DPP250 | |

| PVC sheet | Thickness: 0.2-0.4 mm Width: 100-150 mm | Thickness: 0.2-0.4 mm Width: 160-280 mm |

| PTP aluminum film | Thickness: 0.02-0.04 mm Width: 100-150 mm | Thickness: 0.02-0.04 mm Width: 160-280 mm |

| Cutting frequency | 15-40 times/min | 15-40 times/min |

| Step distance | 45-160mm | 45-160mm |

| Max molding depth | 30mm | 30mm |

| Power | 4.8 KW | 5.55 KW |

| Power supply | 380V 50Hz | 380V 50Hz |

| Machine dimensions | 2250x630x1580mm | 2800x630x1580mm |

| machine weight | 1050 KG | 1850 KG |

Blister sample :

High Speed Automatic Tablet/Capsule Blister Packing Machine (Dpp250)

This machine is suitable for aluminum-plastic, aluminum- aluminum, paper-plastic laminated and sealed packing of capsule, tablet, sweet and deformed tablet in the pharmaceutical, food, Electronic and medical equipment industry. Besides the aluminum automatic feeding, the upper and lower texture, concavo-convex cooperating work-team, multi-stage cylinder heat sealing, automatic pressing and printing batch number and aluminum alloy double heating, the machine also has the following characteristics.

related other blister packing machine list

1. The distance among parts of forming, heat sealing and punching can be adjusted at will to fit for various medicines packing with high precision and strong usability.

2. It pulls with manipulator, adjusts travel at will, operates easily and runs reliably.

3. It adopts cycloid pinwheel to reduce speed and makes the noise low and service life long.

4. It is replaced the mould easily and accurately, adjusts speed stepless and has good performance and high efficiency.

5. The cursor alignment finishes the traction length compensating automatically.

6. Print automatically the batch Number in synchronism with ribbon.

Technical data:

| DPP140 | DPP250 | |

| PVC sheet | Thickness: 0.2-0.4 mm Width: 100-150 mm | Thickness: 0.2-0.4 mm Width: 160-280 mm |

| PTP aluminum film | Thickness: 0.02-0.04 mm Width: 100-150 mm | Thickness: 0.02-0.04 mm Width: 160-280 mm |

| Cutting frequency | 15-40 times/min | 15-40 times/min |

| Step distance | 45-160mm | 45-160mm |

| Max molding depth | 30mm | 30mm |

| Power | 4.8 KW | 5.55 KW |

| Power supply | 380V 50Hz | 380V 50Hz |

| Machine dimensions | 2250x630x1580mm | 2800x630x1580mm |

| machine weight | 1050 KG | 1850 KG |

Blister sample :