| Availability: | |

|---|---|

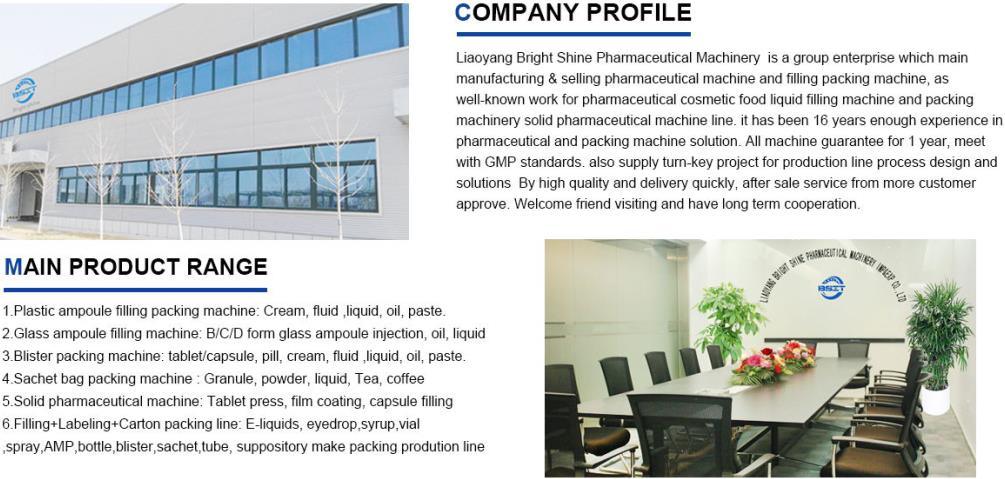

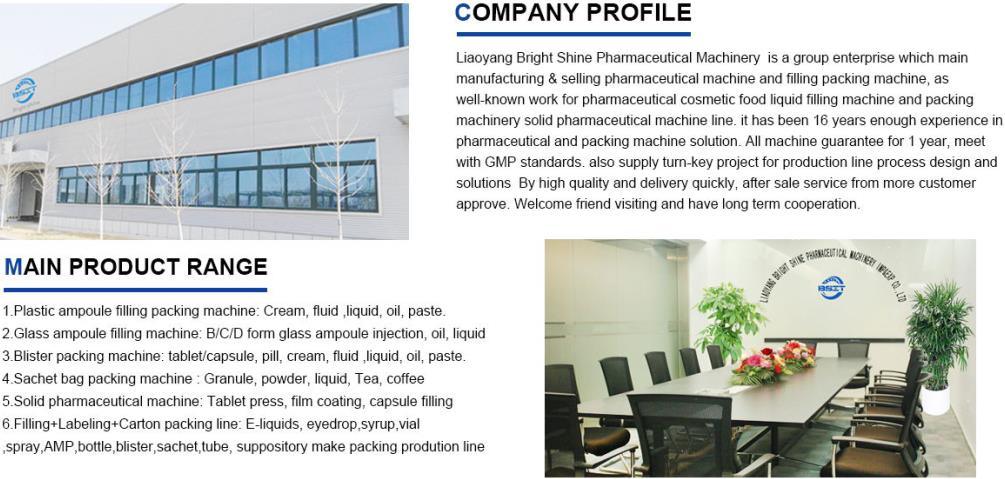

BGB

BSIT

Shanghai, China

10 Sets/Month

L/C, T/T, Western Union, Paypal, Money Gram

1 set

wooden case packing

BGB5F Automatic High-efficiencyTablet Film-Coating Machine/Powder Coating Machine

Main application:

1.BGB-5F High-efficiency coating machine is a special laboratory equipment which used for coating film on traditional Chinese and Western tablets and pills in pilot run.

2. This equipment is manufactured according to the requirements GMP in pharmaceutical industry. The entire outer surface, coating drum (coating pan).spraying device and all parts in contact with medicine are all made of stainless steel.

3.The whole process is controlled by microprocessor-based programmable control system, and also can be controlled manually. The control system has functions such as a wide range of application, selection of running state, control of speed and temperature, control of negative pressure, complete display of control parameters, recording and printing of working state.

4.All the coating operation is carried out under an airtight condition and is free from dust emission and liquid splash. So that this machine is a high quality, high efficiency, reliable, clean, energy saving, easy operation and new type coating equipment which obeys SOP regulations and is widely used as laboratory equipment.

5. all machine guarantee 1 year

6. supply IQ OQ document and English manual user's

Working principle:

The tablet cores (micro-pills, small pills or plain tablets) to be filmcoated make continuous complicated orbital motion within a closed rotating drum under the action of a streamline guide plate. Controlled by computer and according to the optimum technological parameters, they are automatically sprayed with filmcoating medium while hot air under a negative pressure is led in from one side of an air distributing pipe at the center of the drum, clean hot air penetrates through the tablet core layers and is discharged after being collected to the other side of the air distributing pipe by a pore duckbill-shaped (or oval) air paddle embedded in the tablet core layers, so that the filmcoating medium sprayed on the surface of tablet cores will dry rapidly and evenly, thereby forming a layer of solid, compact, neat and smooth surface film.

Sample:

Features:

1.Function of integrated design

2.Control and display the negative pressure in coating pan

3.Display the differential pressure of HEPA filter in supply air

4.Control and display the temperature

5.Control and adjust the atomization surface of slurry

6.Control the program of spray gun and atomization

7.Design of gun clearing and anti-blocking

8.Designed the functions of memory and printing

9.Designed the function of replaceable rotary drum

10.Designed the functions of impulse and dust removing.

Main technical parameters:

| Model | BGB-3F | BGB-5F | BGB-10F |

| Production capacity (kg/run) | 3 | 5 | 10 |

| Three drums for one machine(kg , when bulk density is 1) | 1/3 | 1/3/5 | 3/5/10 |

| Diameter of drum(mm) | 300/380/480 | 300/380/480 | 300/380/480 |

| Speed-adjusting range of film coating drum (rpm) | 6-30 | 6-30 | 6-30 |

| Motor power of main machine (kW) | 0.37 | 0.37 | 0.37 |

| Temperature-regulating range of hot air (° C ) | Normal temperature ~ 80 ° C | Normal temperature ~ 80 ° C | Normal temperature ~ 80 ° C |

| Filtration accuracy of hot air ( mm) | 0.5 mm (100000 grade) | 0.5 mm (100000 grade) | 0.5 mm (100000 grade) |

| Motor power of air heater (kW) | 0.25 | 0.25 | 0.25 |

| Power of air electric heating(kW) | 5 | 5 | 5 |

| Motor power of exhaust machine (kW) | 1.1 | 1.1 | 1.1 |

| Overall dimension of main machine (mm) | 1100×750×1500 | 1250×900×1680 | 1250×900×1680 |

| Weight of main machine (kg) | 380 | 380 | 400 |

![]()

BGB5F Automatic High-efficiencyTablet Film-Coating Machine/Powder Coating Machine

Main application:

1.BGB-5F High-efficiency coating machine is a special laboratory equipment which used for coating film on traditional Chinese and Western tablets and pills in pilot run.

2. This equipment is manufactured according to the requirements GMP in pharmaceutical industry. The entire outer surface, coating drum (coating pan).spraying device and all parts in contact with medicine are all made of stainless steel.

3.The whole process is controlled by microprocessor-based programmable control system, and also can be controlled manually. The control system has functions such as a wide range of application, selection of running state, control of speed and temperature, control of negative pressure, complete display of control parameters, recording and printing of working state.

4.All the coating operation is carried out under an airtight condition and is free from dust emission and liquid splash. So that this machine is a high quality, high efficiency, reliable, clean, energy saving, easy operation and new type coating equipment which obeys SOP regulations and is widely used as laboratory equipment.

5. all machine guarantee 1 year

6. supply IQ OQ document and English manual user's

Working principle:

The tablet cores (micro-pills, small pills or plain tablets) to be filmcoated make continuous complicated orbital motion within a closed rotating drum under the action of a streamline guide plate. Controlled by computer and according to the optimum technological parameters, they are automatically sprayed with filmcoating medium while hot air under a negative pressure is led in from one side of an air distributing pipe at the center of the drum, clean hot air penetrates through the tablet core layers and is discharged after being collected to the other side of the air distributing pipe by a pore duckbill-shaped (or oval) air paddle embedded in the tablet core layers, so that the filmcoating medium sprayed on the surface of tablet cores will dry rapidly and evenly, thereby forming a layer of solid, compact, neat and smooth surface film.

Sample:

Features:

1.Function of integrated design

2.Control and display the negative pressure in coating pan

3.Display the differential pressure of HEPA filter in supply air

4.Control and display the temperature

5.Control and adjust the atomization surface of slurry

6.Control the program of spray gun and atomization

7.Design of gun clearing and anti-blocking

8.Designed the functions of memory and printing

9.Designed the function of replaceable rotary drum

10.Designed the functions of impulse and dust removing.

Main technical parameters:

| Model | BGB-3F | BGB-5F | BGB-10F |

| Production capacity (kg/run) | 3 | 5 | 10 |

| Three drums for one machine(kg , when bulk density is 1) | 1/3 | 1/3/5 | 3/5/10 |

| Diameter of drum(mm) | 300/380/480 | 300/380/480 | 300/380/480 |

| Speed-adjusting range of film coating drum (rpm) | 6-30 | 6-30 | 6-30 |

| Motor power of main machine (kW) | 0.37 | 0.37 | 0.37 |

| Temperature-regulating range of hot air (° C ) | Normal temperature ~ 80 ° C | Normal temperature ~ 80 ° C | Normal temperature ~ 80 ° C |

| Filtration accuracy of hot air ( mm) | 0.5 mm (100000 grade) | 0.5 mm (100000 grade) | 0.5 mm (100000 grade) |

| Motor power of air heater (kW) | 0.25 | 0.25 | 0.25 |

| Power of air electric heating(kW) | 5 | 5 | 5 |

| Motor power of exhaust machine (kW) | 1.1 | 1.1 | 1.1 |

| Overall dimension of main machine (mm) | 1100×750×1500 | 1250×900×1680 | 1250×900×1680 |

| Weight of main machine (kg) | 380 | 380 | 400 |

![]()