HG

BSIT

Shanghai, China

20 Sets/Month

T/T, Western Union

1 set

wooden packing

High Quality pharmaceutical machinery Dryer Granulator for sale

Main Application:

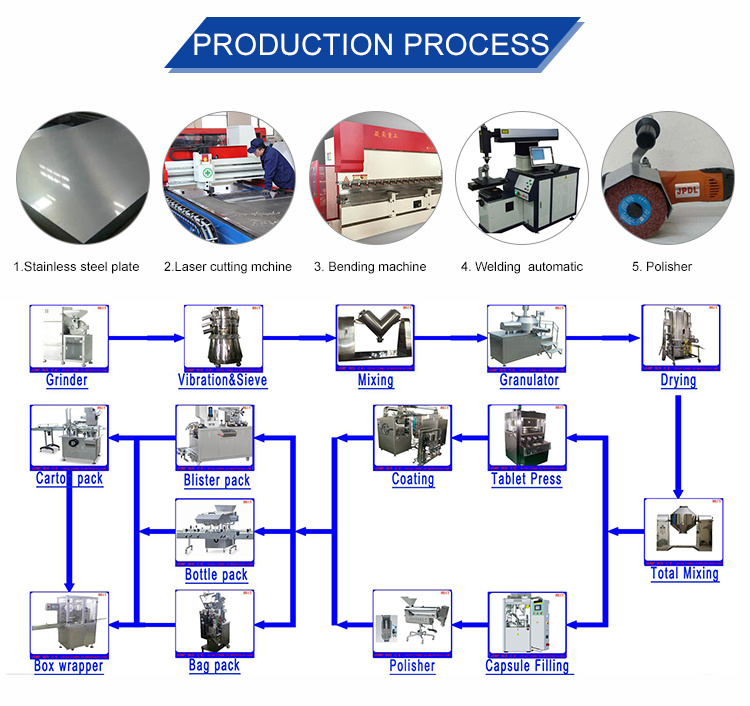

Dryer-granulator compare with traditional vibrating granulator, wet-granulator, fluid-bed granulator machinery, it have powder materical into granlautlor directly meet with customer request. Press materical no need addtional any intermediate and additive, after granulator size even,accumulate density increase, not only control pollution and also reduce other no necessary accessories, reduced by manufactur cost, at same time improved materical apperance and flowality, in order to product next step and stock. Also control dissolubility, porosity and surface area advantage. As granulator shorten be extrusion. No long time heating process, so original materical content don't easy broken. Special as for Heat sensitive product.

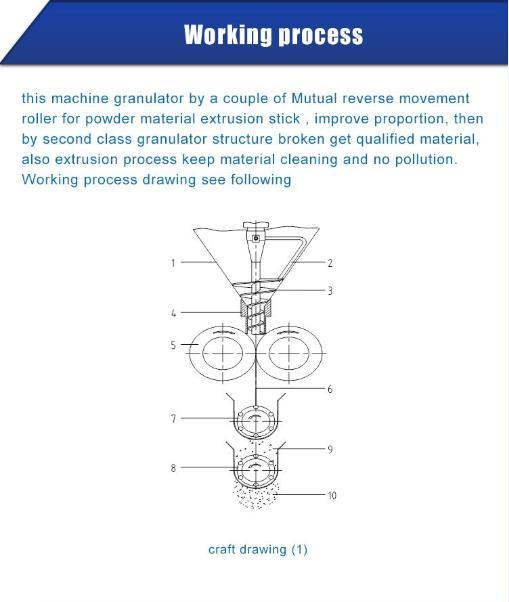

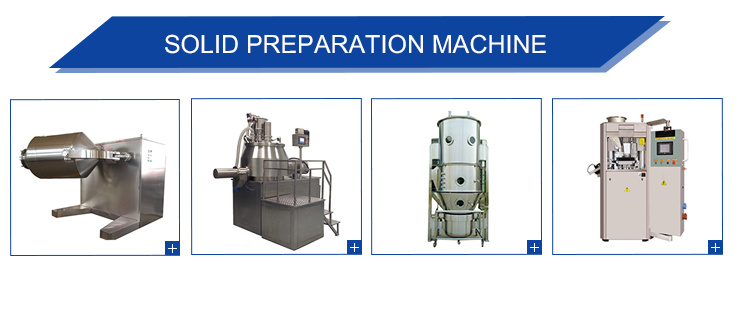

Working Process:

It is by mixed dryer powder materical feed into hopper by manual or vacuum feeder (pneumatic or mechical) by screw transfer feeder into pressure chamber, two high pressure roller press materical into high density slice, by two class granulator system make into request big or small granule and finish granulator process.

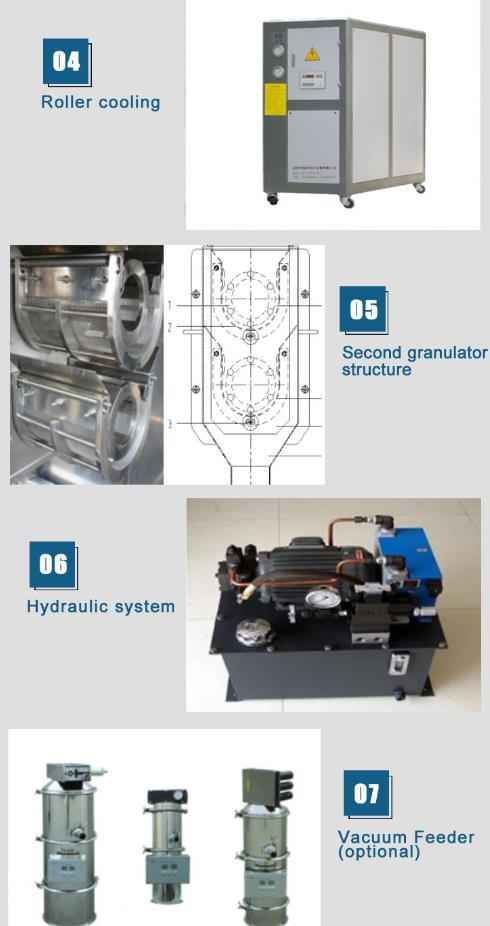

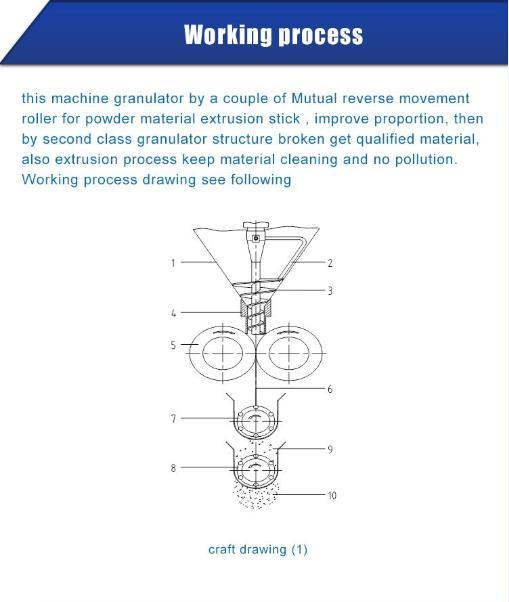

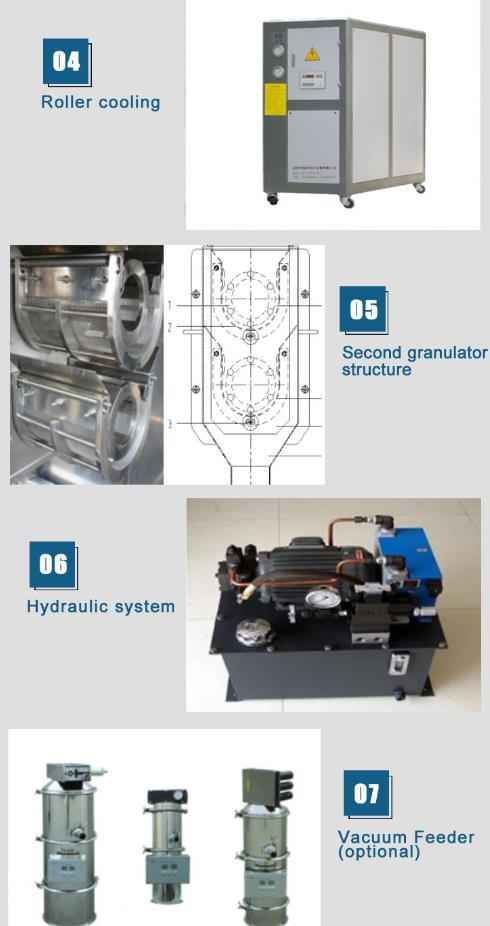

HG series dry-granulator is composed of as following: transfer feed system, extrusion system. The front cover system , water cooling system, granulator system.hydraulic system, engine block combination ,Cover plate assembly,Rotary screen system. Total machine design into body inside and body outside operation board. All driving parts and attached facilities be design inside of machine, working parts design at operation board outside contact with product. middle have multi sealing insulate, it will working at close sealing condition. Easy to dischare and cleaning contact with product. In order to protect deduster leakage, reduce pollution. Reduce puried area meet with pharmaceutical GMP request. We will supply FAT, SAT IQ,OQ,PQ document

Working Process is by mixed dryer powder materical feed into hopper by manual or vacuum feeder (pneumatic or mechical) by screw transfer feeder into pressure chamber, two high pressure roller press materical into high density slice, by two class granulator system make into request big or small granule and finish granulator process.

HG series dry-granulator is composed of as following: transfer feed system, extrusion system. The front cover system , water cooling system, granulator system.hydraulic system, engine block combination ,Cover plate assembly,Rotary screen system. Total machine design into body inside and body outside operation board. All driving parts and attached facilities be design inside of machine, working parts design at operation board outside contact with product. middle have multi sealing insulate, it will working at close sealing condition. Easy to dischare and cleaning contact with product. In order to protect deduster leakage, reduce pollution. Reduce puried area meet with pharmaceutical GMP request. We will supply FAT, SAT IQ,OQ,PQ document.

High Quality pharmaceutical machinery Dryer Granulator for sale

Main Application:

Dryer-granulator compare with traditional vibrating granulator, wet-granulator, fluid-bed granulator machinery, it have powder materical into granlautlor directly meet with customer request. Press materical no need addtional any intermediate and additive, after granulator size even,accumulate density increase, not only control pollution and also reduce other no necessary accessories, reduced by manufactur cost, at same time improved materical apperance and flowality, in order to product next step and stock. Also control dissolubility, porosity and surface area advantage. As granulator shorten be extrusion. No long time heating process, so original materical content don't easy broken. Special as for Heat sensitive product.

Working Process:

It is by mixed dryer powder materical feed into hopper by manual or vacuum feeder (pneumatic or mechical) by screw transfer feeder into pressure chamber, two high pressure roller press materical into high density slice, by two class granulator system make into request big or small granule and finish granulator process.

HG series dry-granulator is composed of as following: transfer feed system, extrusion system. The front cover system , water cooling system, granulator system.hydraulic system, engine block combination ,Cover plate assembly,Rotary screen system. Total machine design into body inside and body outside operation board. All driving parts and attached facilities be design inside of machine, working parts design at operation board outside contact with product. middle have multi sealing insulate, it will working at close sealing condition. Easy to dischare and cleaning contact with product. In order to protect deduster leakage, reduce pollution. Reduce puried area meet with pharmaceutical GMP request. We will supply FAT, SAT IQ,OQ,PQ document

Working Process is by mixed dryer powder materical feed into hopper by manual or vacuum feeder (pneumatic or mechical) by screw transfer feeder into pressure chamber, two high pressure roller press materical into high density slice, by two class granulator system make into request big or small granule and finish granulator process.

HG series dry-granulator is composed of as following: transfer feed system, extrusion system. The front cover system , water cooling system, granulator system.hydraulic system, engine block combination ,Cover plate assembly,Rotary screen system. Total machine design into body inside and body outside operation board. All driving parts and attached facilities be design inside of machine, working parts design at operation board outside contact with product. middle have multi sealing insulate, it will working at close sealing condition. Easy to dischare and cleaning contact with product. In order to protect deduster leakage, reduce pollution. Reduce puried area meet with pharmaceutical GMP request. We will supply FAT, SAT IQ,OQ,PQ document.