| Availability: | |

|---|---|

FZ

BSIT

Shanghai, China

20 Sets/Month

T/T, Western Union

1 set

wooden packing

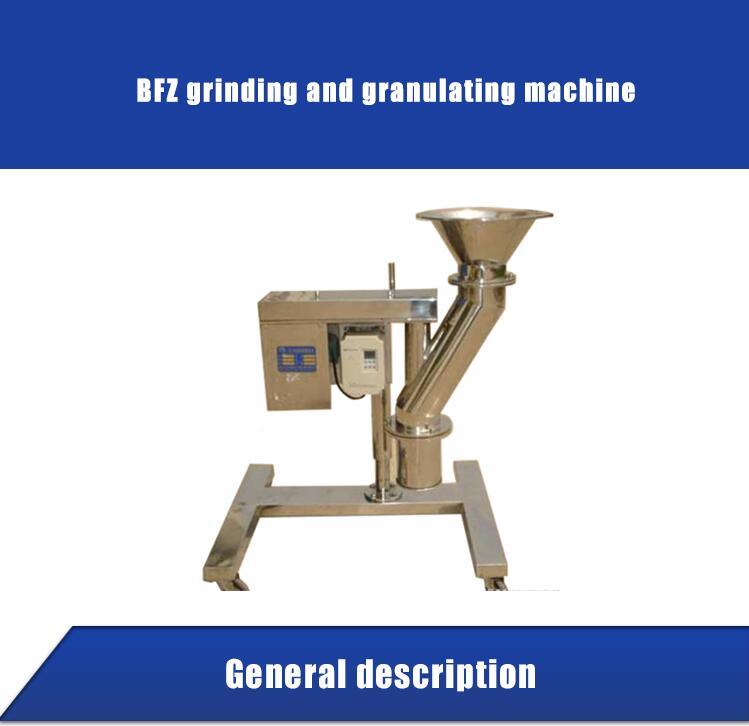

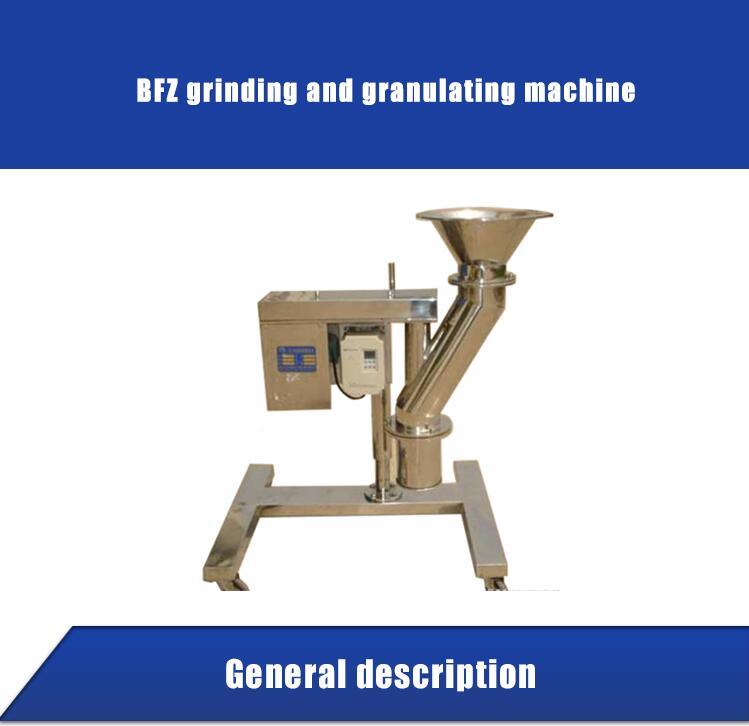

Fz Series factory supply good quality Fast Granulator machine with GMP standards

FZ(B) series grinding and granulating machine is used in pharmaceutical, food, fine chemical processing industries. This machine reaches the world advanced level and conforms to the GMP specification. It is completely made of stainless steel material.

Working principle:

The material to be processed enters into the feed inlet of grinding and granulating machine, drops into the conical sieve chamber. The rotary knife plays a whirling action to the material, and throws the granules to the sieve mesh surface by centrifugal force, The granulates are ground into particles by the shearing action produced by the rotary knife and the sieve mesh, and discharged through the sieve apertures. The size of ground particles can be adjusted by the sieve mesh number, the gap between rotary knife and sieve mesh, and the rotary speed.

Usage:

Pharmacy:

1. Grinding of raw material

2. Granulating of wet material

3. Granulating of dry material

4. Unqualified tablets to be recycled can be granulated according to the requirement of granularity

Food: Grinding of biscuit for recycling

Others: Grinding and granulating of rough raw material

Grinding and granulating of lump raw material.

Features:

1. Thoroughly solving the tough problem of material contaminated by the debris of worn sieve mesh in a pendulum-type granulating machine.

2. The unique patented shaft sealing technology ensures no leakage of lubrication oil.

3. Easy to control granularity

4. No retention dead corner, no material overheating.

5. Less dust, no vibration, low noise.

6. High efficiency, energy saving, large production capacity.

7. Attractive appearance, easy to clean

Main technical parameters:

| model | FZ-150 | FZ-300 | FZ-450 | FZ-700 | FZ-1000 | |

| Item | FZB-150(A) | FZB-300(A) | FZB-450(A) | FZB-700(A) | FZB-1000(A) | |

| Capacity of grinding and granulating machine (kg/h) | 15-150 | 30-300 | 45-450 | 70-700 | 100-1000 | |

| Granularity (mesh) granularity (mesh/h) | 6-80 | |||||

| Drive seat temperature rise(ºC) | <30 | |||||

| Range of speed regulation | FZ :2800rpm FZB:300-3600rpm | |||||

| Motor power (kw ) | 1.5 | 1.5 | 2.2 | 3 | 5.5 | |

| Overall dimension (LXWXH) | 810X445X1345 | 810X445X1345 | 920X445X1430 | 1000X500X1530 | 1100X560X1785 | |

| Height of discharge hopper from the ground level(mm) | 650 | 650 | 690 | 690 | 565 | |

Fz Series factory supply good quality Fast Granulator machine with GMP standards

FZ(B) series grinding and granulating machine is used in pharmaceutical, food, fine chemical processing industries. This machine reaches the world advanced level and conforms to the GMP specification. It is completely made of stainless steel material.

Working principle:

The material to be processed enters into the feed inlet of grinding and granulating machine, drops into the conical sieve chamber. The rotary knife plays a whirling action to the material, and throws the granules to the sieve mesh surface by centrifugal force, The granulates are ground into particles by the shearing action produced by the rotary knife and the sieve mesh, and discharged through the sieve apertures. The size of ground particles can be adjusted by the sieve mesh number, the gap between rotary knife and sieve mesh, and the rotary speed.

Usage:

Pharmacy:

1. Grinding of raw material

2. Granulating of wet material

3. Granulating of dry material

4. Unqualified tablets to be recycled can be granulated according to the requirement of granularity

Food: Grinding of biscuit for recycling

Others: Grinding and granulating of rough raw material

Grinding and granulating of lump raw material.

Features:

1. Thoroughly solving the tough problem of material contaminated by the debris of worn sieve mesh in a pendulum-type granulating machine.

2. The unique patented shaft sealing technology ensures no leakage of lubrication oil.

3. Easy to control granularity

4. No retention dead corner, no material overheating.

5. Less dust, no vibration, low noise.

6. High efficiency, energy saving, large production capacity.

7. Attractive appearance, easy to clean

Main technical parameters:

| model | FZ-150 | FZ-300 | FZ-450 | FZ-700 | FZ-1000 | |

| Item | FZB-150(A) | FZB-300(A) | FZB-450(A) | FZB-700(A) | FZB-1000(A) | |

| Capacity of grinding and granulating machine (kg/h) | 15-150 | 30-300 | 45-450 | 70-700 | 100-1000 | |

| Granularity (mesh) granularity (mesh/h) | 6-80 | |||||

| Drive seat temperature rise(ºC) | <30 | |||||

| Range of speed regulation | FZ :2800rpm FZB:300-3600rpm | |||||

| Motor power (kw ) | 1.5 | 1.5 | 2.2 | 3 | 5.5 | |

| Overall dimension (LXWXH) | 810X445X1345 | 810X445X1345 | 920X445X1430 | 1000X500X1530 | 1100X560X1785 | |

| Height of discharge hopper from the ground level(mm) | 650 | 650 | 690 | 690 | 565 | |