| Availability: | |

|---|---|

ZS-U

BSIT

8422303090

Automatic Middle Speed Suppository Forming Filling Sealing Machine for Zs-U

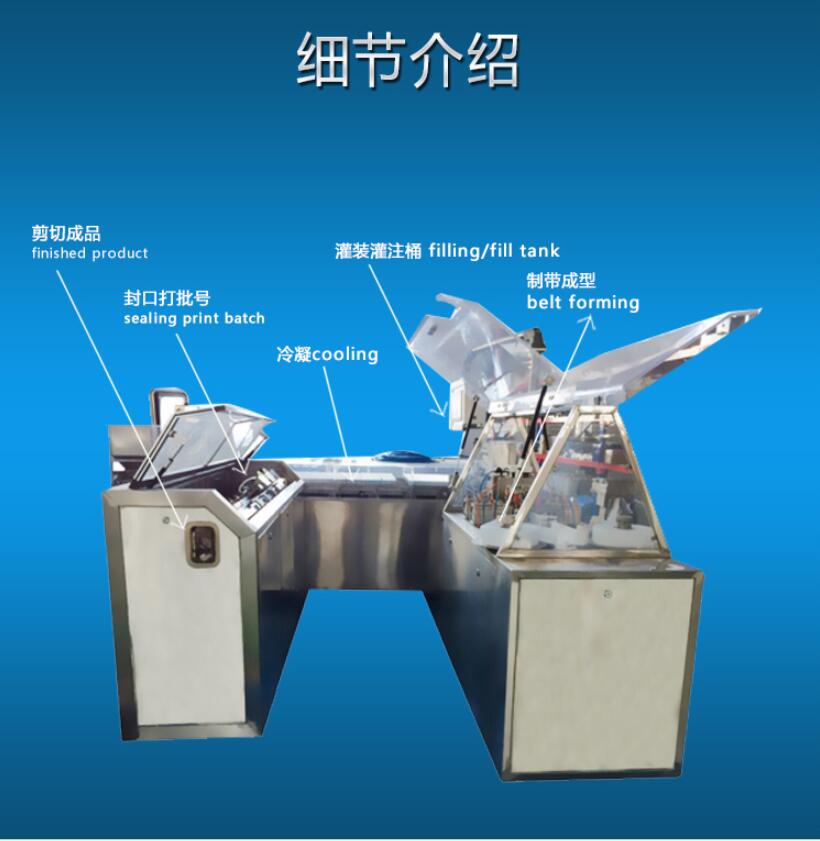

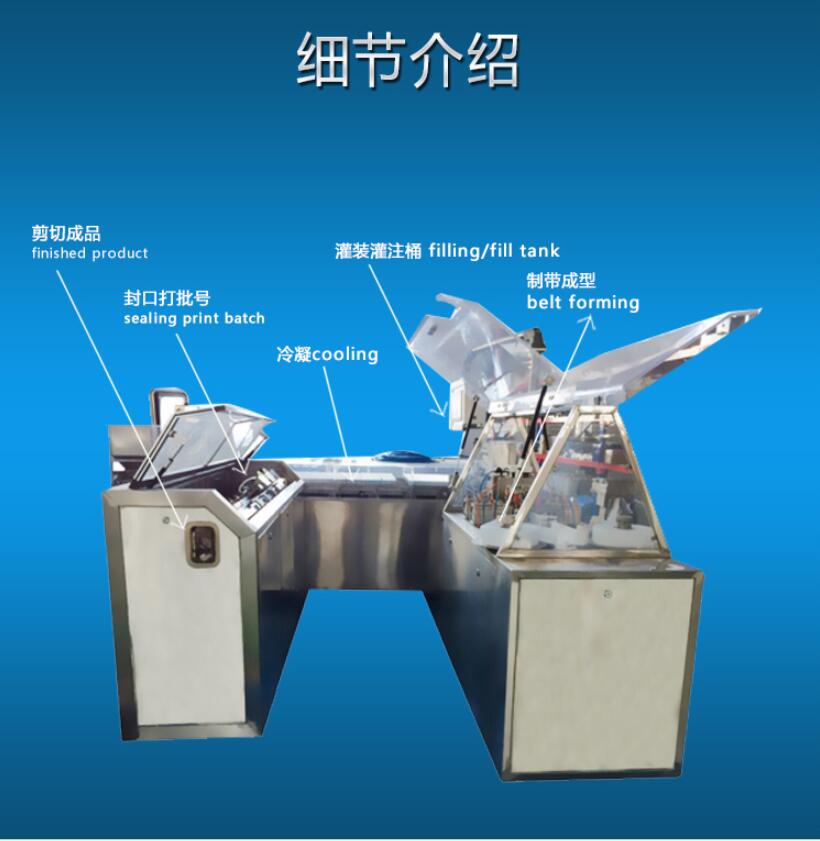

Manufacturing Shell, Perfusing, Cooling Forming and sealed are finished automatically. This machine is equipped with a higher degree of automation . It is controlled by PLC and operated by man-machine interface.

This machine includes four parts:

Suppository belt machine

Suppository perfusing machine

Suppository condensing tunnel

Suppository sealing machine.

The suppository process:

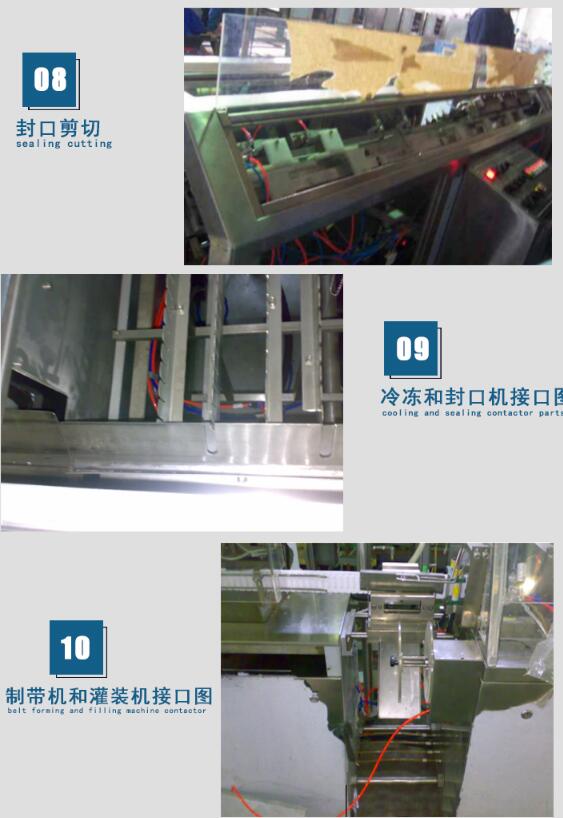

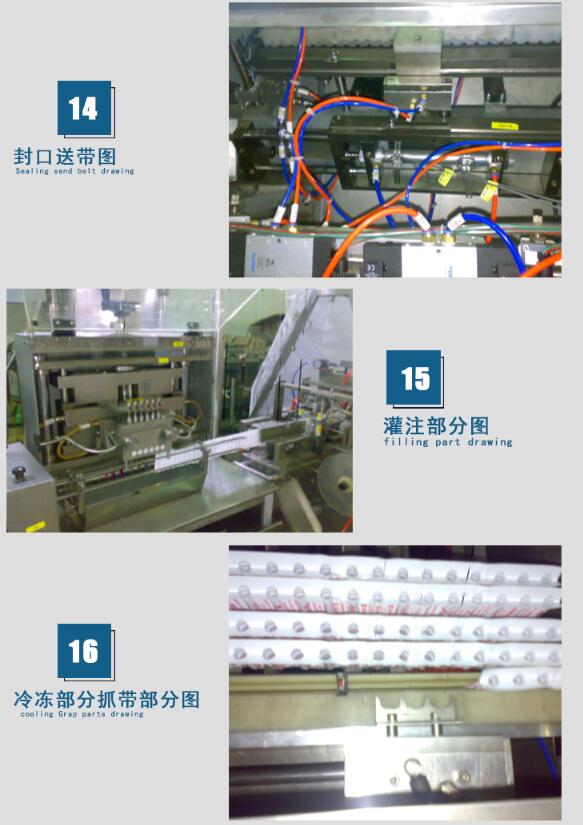

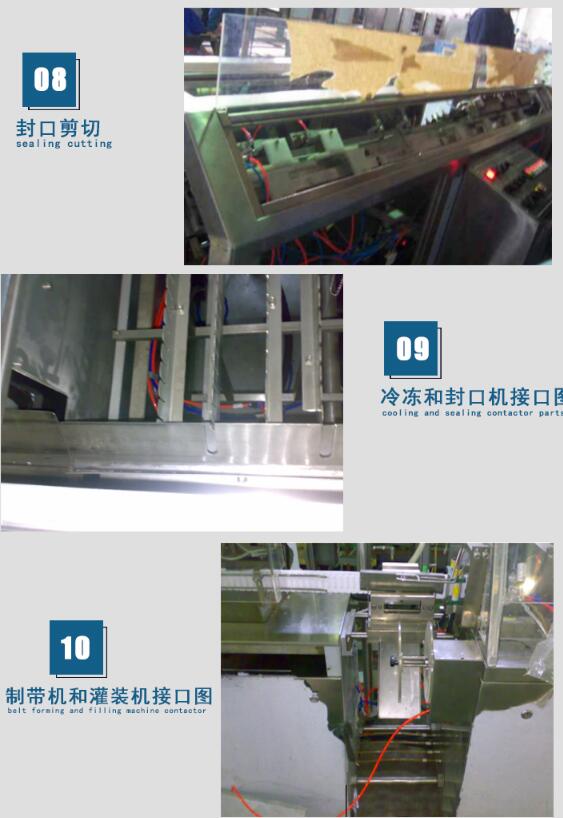

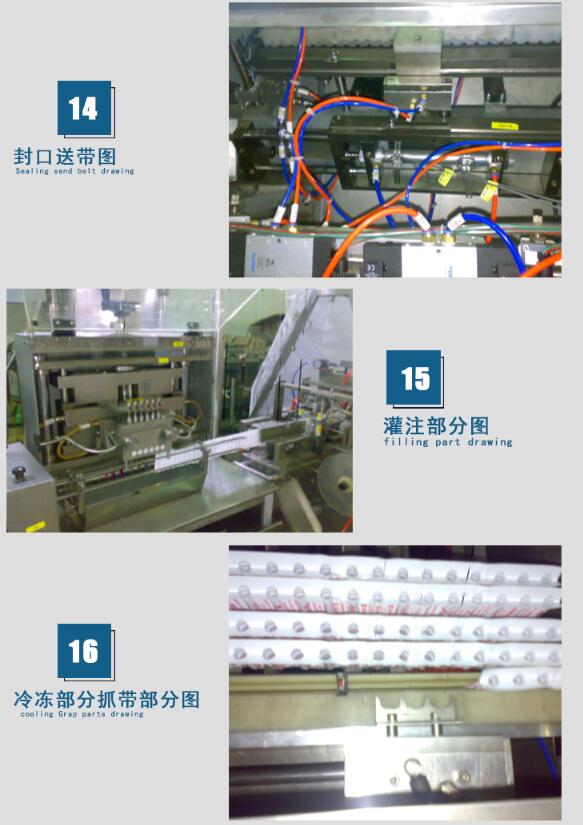

Packaging materials (PVC, PVC / PE) → preheat → weld→ Knurl→ formed by blowing→ do line in mouth→ cut bottom line →perfusion →fixed formed by cooling → preheat→ seal →print production Lot # on above →align the edge →count and cut

Automatic Middle Speed Suppository Forming Filling Sealing Machine for Zs-U working video as following:

![]()

This is a machine that has been developed for the production of suppositories in PVC, PVC+PE. Its working is completely automatic, pneumatically based, controlled by a programmable logic.

Principle of Operation Rolls of bits and pieces of plastic materials(PVC, PVC/PE)is formed with plastic-blowing methods above atmosphere pressure in suppository shell manufacturing machine, automatically enters embedment process.

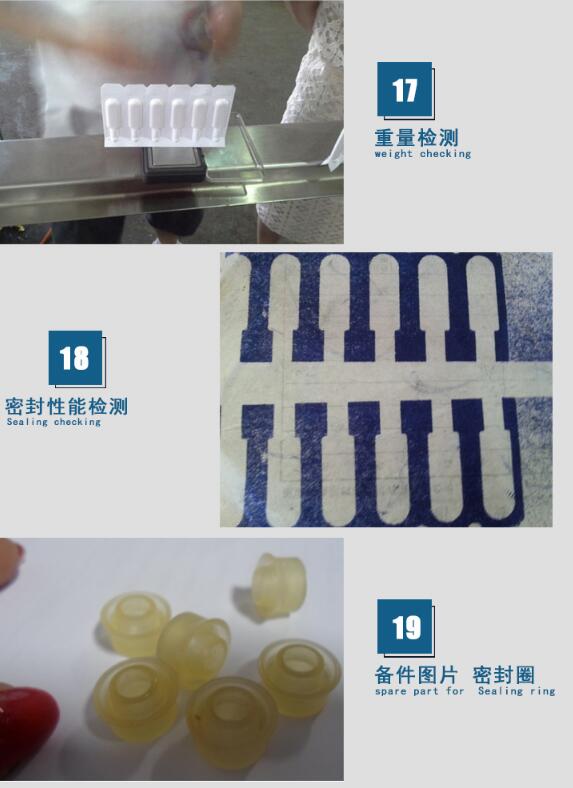

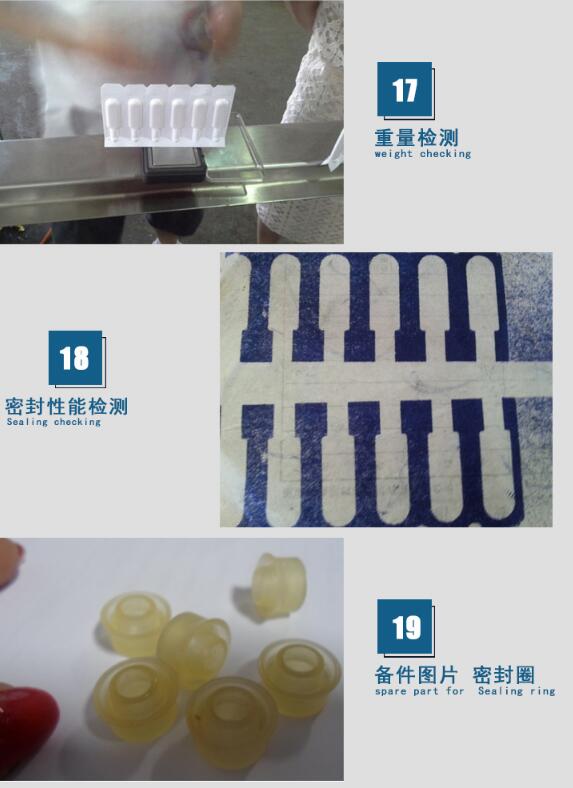

Afeter the mixed medicinal liquid automatically embed into the empty shell through high precision measure pump it is cut into bars of equal length fragment. Through setting in low temperature for a certain time, liquid-solid transmation, it is charged into solid grain. Through process of plastic, seal, printing lot number and cutting, the finished product of suppository is made.

Technological Character:

1. Plugged embedment, accurate position, no drops of medicine, not covered on the bottle and high precision measure.

2. Wide applicability, gelatin medium and traditional Chinese medicine with extremely difficult can be imbedded.

3. PLC programmable control and industrial men-computer operation, high degree automation, easy adjustment, high precision temperature control, reliable work and smooth operation.

4. Large capacity of liquid reserve, constant temperature, automatic control of mixing and surface of liquid.

5. Low pesition of medicinal packing, low labor intensity. Heat preservation equipment of circulation liquid supply and pipe, guaranteeing the medicinal liquid not become solid not become sold when the machine stops.

6. Small area, easy operation.

Bullet Shape mould /Duck mouth/ Torpero Shape drawing is according to water proportion

Technical Parameter:

| Output | 6000-10000suppositories/h |

| Center Distance of Bullet | 17.5mm |

| Center Distance of Duck Bill | 26.25mm |

| Filling Volume | <5ml/PC |

| Allowable Error of granular weightt | ± 2% |

| Volume of storing fluid vessel | 50L |

| Height of feeding | 1400mm |

| Total Power | 13KW |

| Pressure | 0.6Mpa |

| Air Consumption | 1.5M3/Min |

| Water Consumption | 1000kg/h |

| Total Weight | 2000kg |

| Overall Dimension | 3500*3000*2500mm 3490× 2900× 2000mm |

| Shape of Suppository | Bullet form, torpedo form, duck-mouth form and other special form |

| Adaptable cementin | FA-glyceride FA-gelatin polyglycol |

Automatic Middle Speed Suppository Forming Filling Sealing Machine for Zs-U

Manufacturing Shell, Perfusing, Cooling Forming and sealed are finished automatically. This machine is equipped with a higher degree of automation . It is controlled by PLC and operated by man-machine interface.

This machine includes four parts:

Suppository belt machine

Suppository perfusing machine

Suppository condensing tunnel

Suppository sealing machine.

The suppository process:

Packaging materials (PVC, PVC / PE) → preheat → weld→ Knurl→ formed by blowing→ do line in mouth→ cut bottom line →perfusion →fixed formed by cooling → preheat→ seal →print production Lot # on above →align the edge →count and cut

Automatic Middle Speed Suppository Forming Filling Sealing Machine for Zs-U working video as following:

![]()

This is a machine that has been developed for the production of suppositories in PVC, PVC+PE. Its working is completely automatic, pneumatically based, controlled by a programmable logic.

Principle of Operation Rolls of bits and pieces of plastic materials(PVC, PVC/PE)is formed with plastic-blowing methods above atmosphere pressure in suppository shell manufacturing machine, automatically enters embedment process.

Afeter the mixed medicinal liquid automatically embed into the empty shell through high precision measure pump it is cut into bars of equal length fragment. Through setting in low temperature for a certain time, liquid-solid transmation, it is charged into solid grain. Through process of plastic, seal, printing lot number and cutting, the finished product of suppository is made.

Technological Character:

1. Plugged embedment, accurate position, no drops of medicine, not covered on the bottle and high precision measure.

2. Wide applicability, gelatin medium and traditional Chinese medicine with extremely difficult can be imbedded.

3. PLC programmable control and industrial men-computer operation, high degree automation, easy adjustment, high precision temperature control, reliable work and smooth operation.

4. Large capacity of liquid reserve, constant temperature, automatic control of mixing and surface of liquid.

5. Low pesition of medicinal packing, low labor intensity. Heat preservation equipment of circulation liquid supply and pipe, guaranteeing the medicinal liquid not become solid not become sold when the machine stops.

6. Small area, easy operation.

Bullet Shape mould /Duck mouth/ Torpero Shape drawing is according to water proportion

Technical Parameter:

| Output | 6000-10000suppositories/h |

| Center Distance of Bullet | 17.5mm |

| Center Distance of Duck Bill | 26.25mm |

| Filling Volume | <5ml/PC |

| Allowable Error of granular weightt | ± 2% |

| Volume of storing fluid vessel | 50L |

| Height of feeding | 1400mm |

| Total Power | 13KW |

| Pressure | 0.6Mpa |

| Air Consumption | 1.5M3/Min |

| Water Consumption | 1000kg/h |

| Total Weight | 2000kg |

| Overall Dimension | 3500*3000*2500mm 3490× 2900× 2000mm |

| Shape of Suppository | Bullet form, torpedo form, duck-mouth form and other special form |

| Adaptable cementin | FA-glyceride FA-gelatin polyglycol |