| Availability: | |

|---|---|

BSM125

BSIT

8422303090

Shanghai, China

30 Sets/Year

L/C, T/T, Western Union, Paypal, Money Gram

BSM High Speed Automatic soap/bottle/blister/bag/injector/glue Cartoning Box Packing Machine

Main Introduce:

The equipment is mainly used for the bottle type (round bottle, square bottle,flat bottle ,shaped bottle,etc.),and the cosmetics, food , health care products like bottled items automatic cartoning, to box more than sticks.

Main feature:

1.International famous brand of electrical component such as PLC touch screen, frequency inverters,

2.all product have more inspect device in boxing machine, Automatically check and reject lacking product

on the lack of books, no bottle, box missing unqualified prodct automatic detection and elimination

3.Adopt man-machine interface of operation system. Easy to operate, the automatic display of working speed and counting function

4.automatic folding instructionss 1-4 fold adjustable, and feed into box automatically

5.print 2-4 rows steel seal batch auto at same time

6.Automatic fault Display, alarm and shutdown, display machine operation and repair method

7.Multiple specification of adjustment can be realized in the same boxing machine. The Adjustment is simple and convenient.

8.This boxing machine can work with labeling machine, bottle packing line, blister packing, pillow packing macihne, three-dimensional transparent film packing machine, banding packing machine make production line, improve product quality, improve labor productivity.

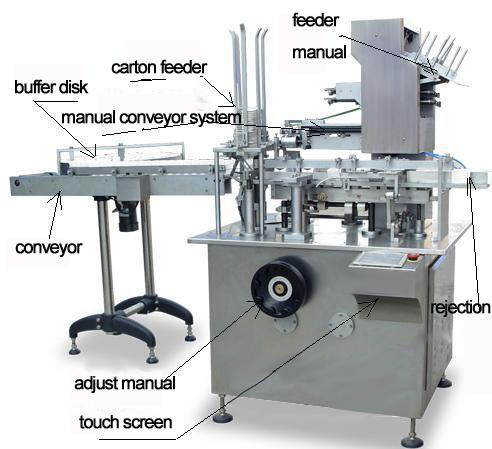

Main structure:

blister(bottle or injection) conveyor

fold device

Manual conveyor · push feeder

·Send box structure

·printing

no manual(bottle,blister,injection) reject system auto

· electric control system

·power system

· cam driving system

· open box device

Range: for pharmay factory, health food or costomatic factory

Machine advange: save worker( 1 set of machine instead of 10 worker) easy to arrange, improve product quality and competition

All kinds of tube/bottle into carton

all kinds of blister into carton

Carton box packing machine drawing:

E-Liquid(E-liquids)E-cig filling sample as reference

1 International famous brand of electrical component such as PLC touch screen, frequency inverters, etc.

2 Adopt human-machine operation system.

3 Automatically stop when machine is overload.

4 Automatically reject lacking of package product and leaflet.

5 Automatically display trouble, Alarm and count finished products.

6 Stable performance, operation is easy.

Technical parameters:

| Item | Parameters | |

| Encasing speed | 30-120 boxes/min | |

| Box | Quality requirement | 250-350g/ M*M [ Base on carton size ] |

| Dimension range ( L× W× H ) | ( 65-150 ) mm× ( 30-85 ) mm× ( 14-50 ) mm | |

| C | Quality requirement | 60-70g/ M*M |

| Unfolded leaflet specification ( L× W ) | ( 80-250 )mm× ( 90-170 )mm | |

| Fold range ( L× W ) | [ 1-4 ] Fold | |

| Compressed air | Working pressure | ≥ 0.6mpa |

| Air consumption | 120-160L/min | |

| Power supply | 220V 50HZ | |

| Main motor power | 0.75kw | |

| Machine dimension ( L× W× H ) | 2400 mm × 1140 mm × 1800 mm | |

| Machine weight | about 1200kg | |

BSM High Speed Automatic soap/bottle/blister/bag/injector/glue Cartoning Box Packing Machine

Main Introduce:

The equipment is mainly used for the bottle type (round bottle, square bottle,flat bottle ,shaped bottle,etc.),and the cosmetics, food , health care products like bottled items automatic cartoning, to box more than sticks.

Main feature:

1.International famous brand of electrical component such as PLC touch screen, frequency inverters,

2.all product have more inspect device in boxing machine, Automatically check and reject lacking product

on the lack of books, no bottle, box missing unqualified prodct automatic detection and elimination

3.Adopt man-machine interface of operation system. Easy to operate, the automatic display of working speed and counting function

4.automatic folding instructionss 1-4 fold adjustable, and feed into box automatically

5.print 2-4 rows steel seal batch auto at same time

6.Automatic fault Display, alarm and shutdown, display machine operation and repair method

7.Multiple specification of adjustment can be realized in the same boxing machine. The Adjustment is simple and convenient.

8.This boxing machine can work with labeling machine, bottle packing line, blister packing, pillow packing macihne, three-dimensional transparent film packing machine, banding packing machine make production line, improve product quality, improve labor productivity.

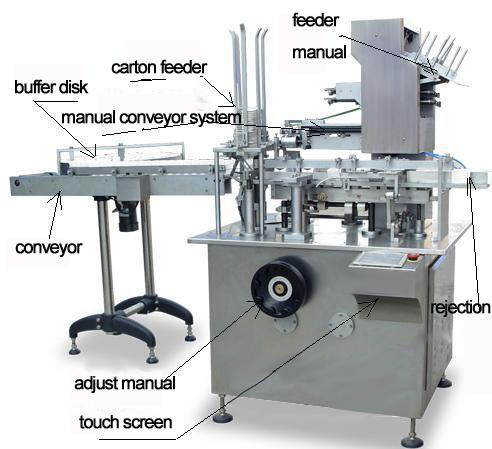

Main structure:

blister(bottle or injection) conveyor

fold device

Manual conveyor · push feeder

·Send box structure

·printing

no manual(bottle,blister,injection) reject system auto

· electric control system

·power system

· cam driving system

· open box device

Range: for pharmay factory, health food or costomatic factory

Machine advange: save worker( 1 set of machine instead of 10 worker) easy to arrange, improve product quality and competition

All kinds of tube/bottle into carton

all kinds of blister into carton

Carton box packing machine drawing:

E-Liquid(E-liquids)E-cig filling sample as reference

1 International famous brand of electrical component such as PLC touch screen, frequency inverters, etc.

2 Adopt human-machine operation system.

3 Automatically stop when machine is overload.

4 Automatically reject lacking of package product and leaflet.

5 Automatically display trouble, Alarm and count finished products.

6 Stable performance, operation is easy.

Technical parameters:

| Item | Parameters | |

| Encasing speed | 30-120 boxes/min | |

| Box | Quality requirement | 250-350g/ M*M [ Base on carton size ] |

| Dimension range ( L× W× H ) | ( 65-150 ) mm× ( 30-85 ) mm× ( 14-50 ) mm | |

| C | Quality requirement | 60-70g/ M*M |

| Unfolded leaflet specification ( L× W ) | ( 80-250 )mm× ( 90-170 )mm | |

| Fold range ( L× W ) | [ 1-4 ] Fold | |

| Compressed air | Working pressure | ≥ 0.6mpa |

| Air consumption | 120-160L/min | |

| Power supply | 220V 50HZ | |

| Main motor power | 0.75kw | |

| Machine dimension ( L× W× H ) | 2400 mm × 1140 mm × 1800 mm | |

| Machine weight | about 1200kg | |